Bolt Printing shares details of its in-house manufacturing and workflow practices designed to meet tight deadlines for custom apparel orders nationwide.

When design, printing, and packaging are handled under one roof, we can monitor quality and timelines more closely”

— Lana Corsano

BROOKFIELD, CT, UNITED STATES, August 14, 2025 /EINPresswire.com/ -- Bolt Printing has outlined the production practices it uses to meet rapid turnaround requirements for custom apparel and promotional products.

The company reports that demand for short-notice orders has increased in recent years, particularly for events with fixed start dates such as races, reunions, product launches, and school activities.According to Founder & CEO Lana Corsano, Bolt Printing’s approach centers on maintaining all production stages within its facility. “When design, printing, and packaging are handled under one roof, we can monitor quality and timelines more closely,” Corsano said.

Key operational elements include:

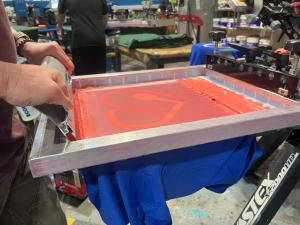

In-House Manufacturing: Consolidating production enables direct oversight from concept to shipment.

Experienced Staff: Team members bring years of experience in screen printing, embroidery, and customer service.

Workflow Optimization: Production lines are arranged to minimize delays and maintain quality control checks.

Corsano noted that the company’s internal culture emphasizes accountability and collaboration, which she believes supports on-time delivery.

Founded in 2009, Bolt Printing serves clients nationwide, including businesses, schools, nonprofits, and event organizers. The company offers a range of custom-printed t-shirts and embroidered products, with production capacity designed to accommodate both planned and urgent orders.

No comments:

Post a Comment